In an effort to redress the dire postwar balance of payments situation through a manufacturing export drive, it only took two years for the idea to be brought to launch. The key to the design brief was minimal cost. Healey instructed Gerry Coker to design the chassis and body, but to keep costs low, the design maximised existing BMC components. So the engine, a 1949 designed A series unit. Gearbox suspension and braking, from the Austin A35, steering, wheels and electrics from the Morris Minor.

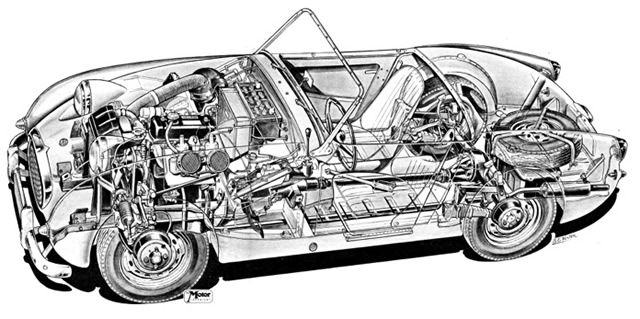

Pope’s immaculate cutaway drawings show the construction of the car in every detail.

This wonderful BMC footage shows a test drive. Typical British weather! (No sound)

There were more than ten suppliers for the key parts: Lockheed for brakes, Lucas for electrics, Borg and Beck Clutch, John Thompson for body/chassis components, Armstrong, shock absorbers, pressed steel, Rubry Owen, instruments, Smiths, down to items such as the windscreen washers by Tudor, chrome components such as petrol caps etc, Wiltmott Breeden. All brought together for assembly in the massive BMC Abingdon factory.

Frogeye is third from the left in the main picture. Waiting for export to Los Angeles. Sadly the Abingdon factory is no more.